Product name:Silicon nitride powder

Molecular formula:Si3N4

Molecular weight:140.28

CAS#:12033-89-5

Melting point:1900℃

Density:3.17 g/cm3

Appearance form:White-gray powder

Thermal conductivity:(2-155)W/(m·K)

Coefficient of thermal expansion (20~1000℃):(2.8~3.2)×10-6℃-1

Mohs hardness:9~9.5

Microhardness:32630 MPa

Vickers hardness:2200

Flexural strength:850 MPa

Storage method:Closed at room temperature, cool and ventilated dry place.

Silicon nitride is one of the highest performing technical ceramics in the oxide and non-oxide groups.

Silicon nitride ceramics have the characteristics of high strength and high temperature resistance, and its comprehensive mechanical properties are the best in ceramic materials, and it is the first candidate material for ceramics for heat engine parts.

(1) In the machinery industry, silicon nitride ceramics are used as bearing balls, rollers, ball seat rings, tool molds, new ceramic tools, pump plungers, mandrel sealing materials, etc.; In the chemical industry, silicon nitride ceramics are used as wear-resistant and corrosion-resistant components. Such as ball valves, pump bodies, combustion vaporizers, filters, etc.;

(2) In the metallurgical industry, silicon nitride ceramics have self-lubricating properties due to high temperature resistance, small friction coefficient. Stable to most metal and alloy solutions, therefore, it can make metal material processing tools, such as knuckle mandrels, extrusion, wire picks, rolls, transfer rollers, heating element fixtures, thermocouple camps, metal heat treatment supports, crucibles, aluminum liquid guide camps, aluminum package linings, etc.; Silicon nitride ceramic materials are also widely used in electronics, military and nuclear industries.

(3) Due to its unique intersection of chemical and thermodynamic properties, silicon nitride can be easily deployed in some of the harshest working environments in the world. Auto-pressed silicon nitride has excellent high-temperature performance and is ideal for sealing face assemblies in challenging conditions, including boiler water reactor pumps, pressurized water reactor pumps, corrosive boric acid water services and inside rotating bearings.

(4) Pump components composed of silicon nitride are also used in the oil and gas industry, as well as in the petrochemical industry as a whole. The chemical integrity of silicon nitride makes it suitable for surfaces (impellers, shafts, seals, etc.) in pumps that are frequently exposed to abrasive slurries and corrosive fluids.

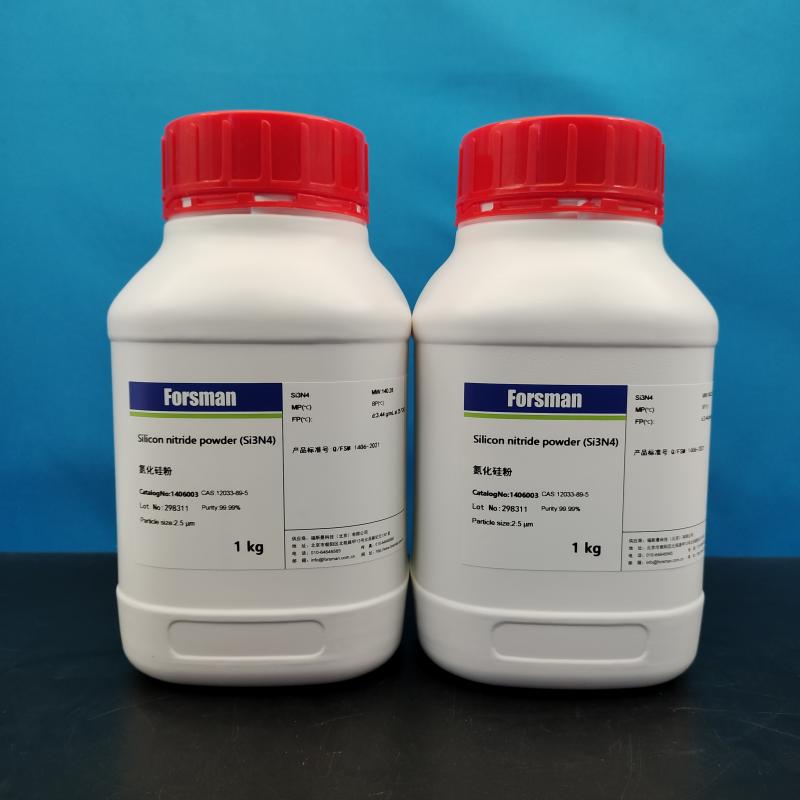

Forsman’s silicon nitride product series are all high-purity, according to the appearance of silicon nitride powder, silicon nitride balls; The factory can produce nano-level, sub-micron-level, micron-level and other different particle sizes of products, can supply the smallest particle size of 25 nm, many products in the 1-5 μm particle size range, have achieved industrial customized production. It can be provided with 2kg, 10kg, 25kg and other tonnage levels, and can accept other particle size customization from customers.

Silicon nitride balls, silicon nitride fibers (chopped)

Find the above details in the product center - Profiles

Fig. 1406004 Silicon nitride powder 0.7 μm

Fig. Silicon nitride powder packaging